Home > Houston Refinery Accident Lawyers

Houston Plant & Refinery Accident Lawyers

Undefeated Houston Plant and Refinery Explosion Attorneys

Workers at industrial plants and refineries face a constant threat of catastrophic fires, explosions, and serious injuries every day they’re on the job.

That’s why it’s critical that plant and refinery operators ensure equipment is properly operated and maintained and that volatile chemicals are safely isolated and stored. Operators are also required, by federal law, to comply with all applicable safety regulations and procedures and provide workers with the safety training and PPE needed to ensure their safety on the job.

Contact Our Houston Refinery Accident Lawyers for a Free Consult at 1-888-603-3636 or by Clicking Here

Our Undefeated Plant and Refinery Accident Lawyers have won Billions—including a $100 Million settlement and the #1 Largest Oilfield Burn Injury Settlement in History—for injured industrial workers across Texas, Louisiana, and the United States.

If you or a loved one were injured, severely burned, or tragically killed while working at a plant or refinery, our Refinery Injury Attorneys will devote whatever time and resources are necessary to holding the company accountable and ensuring that you and your family receive the largest recovery possible for all of your injuries and losses.

Call 1-888-603-3636, use the “Chat Now” button on our site or Click Here to send us a confidential email.

Plant and Refinery Explosions are on the Rise in Texas

As the capital of the petrochemical industry, Texas is home to hundreds of plants and refineries, many of which have experienced devastating fires and explosions in recent years:

- Blue Dolphin Nixon Refinery

- BP Texas City

- Calumet Lubricants San Antonio Refinery

- Citgo Corpus Christi Refinery

- Delek Big Spring Refinery

- Dalek Tyler Refinery

- Dow Chemical Bayport Plant

- Flint Hills Resources Corpus Christi Complex

- ExxonMobil Baytown Refinery

- ExxonMobil Beaumont Refinery

- ExxonMobil Olefins Plant, Baytown

- Intercontinental Terminals Co. (ITC), Deer Park, and Pasadena

- KMCO Chemical Plant, Crosby

- Kuraray America Chemical Plant, Pasadena

- LyondellBasell Houston Refinery

- Marathon Petroleum Galveston Bay Refinery

- Petrobras Pasadena Refinery

- Phillips 66 Sweeney Refinery

- Praxair Hydrogen Complex, Texas City

- Shell Oil Deer Park Refinery

- Stratnor Independent Refinery Houston

- Total Port Arthur Refinery

- TPC Port Neches Chemical Plant

- Tri-Chem Industries, Cresson

- S. Polyco Plant, Ennis

- Valero Corpus Christi East & West Refinery

- Valero Houston Refinery

- Valero McKee Refinery, Sunray

- Valero Port Arthur Refinery

- Valero Texas City Refinery

- Valero Three Rivers Refinery

- Western Refining El Paso Refinery

- WRB Refining LP by Phillips 66/Cenovus Borger Refinery

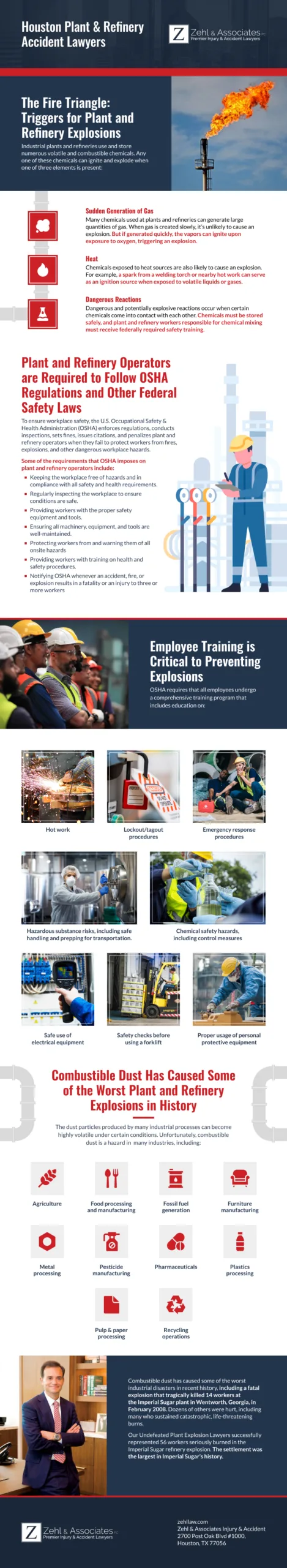

Plant and Refinery Operators are Required to Follow OSHA Regulations and Other Federal Safety Laws

To ensure workplace safety, the U.S. Occupational Safety & Health Administration (OSHA) enforces regulations, conducts inspections, sets fines, issues citations, and penalizes plant and refinery operators when they fail to protect workers from fires, explosions, and other dangerous workplace hazards.

Some of the requirements that OSHA imposes on plant and refinery operators include:

- Keeping the workplace free of hazards and in compliance with all safety and health requirements.

- Regularly inspecting the workplace to ensure conditions are safe.

- Providing workers with the proper safety equipment and tools.

- Ensuring all machinery, equipment, and tools are well-maintained, in good repair, and replaced as needed.

- Protecting workers from and warning them of all onsite hazards

- Providing workers with training on health and safety procedures, including regular training reviews.

- Notifying OSHA whenever an accident, fire, or explosion results in a fatality or an injury to three or more workers

1 Worker is Killed Every 111 Minutes at Texas Plants and Refineries

Despite the extensive state and federal safety regulations, thousands of workers are injured and killed at plants and refineries every year. In fact, according to the U.S. Bureau of Labor Statistics, 1 worker was killed ever 111 minutes in Texas in 2022.

Texas alone recorded 608 work-related fatalities, more than any other state in the nation, including 18 deaths that resulted from an explosion or fire.

The Fire Triangle: Triggers for Plant and Refinery Explosions

Industrial plants and refineries use and store numerous volatile and combustible chemicals. Any one of these chemicals can ignite and explode when one of three elements is present:

- Sudden Generation of Gas: Many chemicals used at plants and refineries can generate large quantities of gas. When gas is created slowly, it’s unlikely to cause an explosion. But if generated quickly, the vapors can ignite upon exposure to oxygen, triggering an explosion.

- Heat: Chemicals exposed to heat sources are also likely to cause an explosion. For example, a spark from a welding torch or nearby hot work can serve as an ignition source when exposed to volatile liquids or gases.

- Dangerous Reactions: Dangerous and potentially explosive reactions occur when certain chemicals come into contact with each other. Chemicals must be stored safely, and plant and refinery workers responsible for chemical mixing must receive federally required safety training.

Boiling Liquid Expanding Vapor Explosions (BLEVEs) at Plants and Refineries

BLEVEs (Boiling Liquid Expanding Vapor Explosions) occur when a liquid stored in a sealed pressure vessel begins to boil. As the substance grows hotter, it eventually converts to gas and takes up more space than what is required by its liquid form. If the vessel lacks enough room for the gas, it will eventually rupture and explode.

A second-stage BLEVE can occur if a vessel releases combustible vapor into an area where it then mixes with air in the presence of an ignition source.

According to the U.S. Chemical Safety Board, the Williams Olefins explosion that tragically killed two workers in Geismar, Louisiana, on June 13, 2013, involved a BLEVE. Our Undefeated Explosion Lawyers won highly favorable (and confidential) settlements for over 65 workers injured during the Williams Geismar explosion.

BLEVEs also contributed to a series of explosions that destroyed the TPC plant in Port Neches, Texas, in November 2019, as well as the ITC Deer Park tank fire in Houston that same year.

How Poorly Maintained Equipment and Facilities Contribute to Plant and Refinery Explosions

From boilers, pressure valves, and alarms to catalysts, reagents, and storage tanks, any plant and refinery equipment that isn’t adequately maintained, free of defects, or in good working order significantly increases the risk of an explosion or other catastrophic accident.

For example, the failure of alarms to warn operators of abnormal conditions in the isomerization unit contributed to the deadly explosion that tragically killed 15 workers at the BP Texas City Refinery Explosion in March 2005. The CSB also cited equipment failure as a factor in the 2013 Williams Geismar explosion, the 2018 Kuraray American explosion in Pasadena, Texas, and the 2019 KMCO explosion in Crosby.

Our firm recovered highly favorable (and confidential) settlements for over 200 workers injured during the BP Texas City refinery explosion.

Employee Training is Critical to Preventing Explosions

Because plants and refineries are dangerous worksites, OSHA requires that all employees undergo a comprehensive training program that includes education on:

- Hot work

- Lockout/tagout procedures

- Hazardous substance risks, including safe handling and prepping for transportation.

- Chemical safety hazards, including control measures for chemical safety

- Emergency response procedures

- Proper usage of personal protective equipment

- Safe use of electrical equipment

- Safety checks that should be performed before using a forklift

Plant and refinery operators must also ensure that all rules are clearly communicated and consistently enforced. The confusion created by unclear, unknown, and inconsistent safety policies is dangerous and potentially fatal for plant and refinery workers

Corrossion is a Leading Cause of Chemical Releases and Explosions

Industrial plants and refineries rely on miles off pipelines to transport liquids and gases throughout the facility, storage tanks and pressure vessels to keep chemicals and other hazardous substances safe and secure, and an array of machinery to process these materials. But over time, the metal comprising this equipment can wear down, oxidize, corrode, and ultimately fail.

While the signs of corrosion are sometimes visible, this is not always the case. Unfortunately, unseen corrosion is often so subtle that even highly trained inspectors may miss it. Corrosion can also go unseen if it occurs in an area that isn’t easy to access.

Unseen corrosion will gradually worsen and could eventually allow volatile liquids or gases to leak undetected. If these hazardous substances make contact with an ignition source, an explosion is inevitable.

Contaminated Chemicals Can Trigger an Explosion

Industrial plants and refineries use and mix an array of highly reactive chemicals in their processes, including ammonium nitrate, phosphorus, and potassium, to name just a few. Because of their sensitive and volatile nature, these chemicals must be handled and stored correctly to prevent catastrophic explosions.

Adulterated and contaminated chemicals can also lead to disastrous consequences. To ensure the safety of all workers, plant and refinery operators must adhere to strict regulations governing what type and quality of chemicals can be used onsite.

The Use of Natural Gas Increases Risk of Explosions

Plants and refineries sometimes use natural gas to clean and clear fuel gas piping systems.

This “gas blow” technique uses high pressure to push natural gas through the piping and expel any potentially damaging foreign materials. This process is highly complex and requires accurate cleaning force calculations and detailed sequencing steps.

Unfortunately, natural gas clearing procedures have caused industrial disasters in the past, including a deadly explosion at a Kleen Energy site in Connecticut that tragically killed six people and injured more than 50 others in February 2010. OSHA investigators later noted that the responsible companies failed to convene a safety meeting before the cleaning project, which would have allowed workers to review safety procedures and potential hazards.

Combustible Dust Has Caused Some of the Worst Plant and Refinery Explosions in History

The dust particles produced by many industrial processes can become highly volatile under certain conditions. Unfortunately, combustible dust is a hazard in many industries, including:

- Agriculture, including grain, tobacco, sugar, and fertilizer processing

- Food processing and manufacturing

- Fossil fuel generation

- Furniture manufacturing

- Metal processing

- Pesticide manufacturing

- Pharmaceuticals

- Plastics processing

- Pulp and paper processing

- Recycling operations

Industrial dust in a sufficient quantity will fuel an explosion if it is allowed to come into contact with an ignition source. Secondary explosions will occur if the initial blast disperses additional combustible dust particles into the air and they make contact with heat. In fact, according to OSHA, most deaths in combustible dust explosions are the result of secondary explosions.

Combustible dust has caused some of the worst industrial disasters in recent history, including a fatal explosion that tragically killed 14 workers at the Imperial Sugar plant in Wentworth, Georgia, in February 2008. Dozens of others were hurt, including many who sustained catastrophic, life-threatening burns.

Unfortunately, efforts to establish a mandatory combustible dust standard in the wake of the Imperial Sugar disaster were ultimately derailed by the Trump administration. However, OSHA has established the Combustible Dust National Emphasis Program (NEP), including guidelines to help worksites mitigate dust hazards. Those voluntary guidelines recommend that employers:

- Make every effort to contain dust within process equipment.

- Utilize a dust collection system to capture any uncontained dust at the point of release.

- Clean up any dust not contained or captured.

Our Undefeated Plant Explosion Lawyers successfully represented 56 workers seriously burned in the Imperial Sugar refinery explosion. The settlement was the largest in Imperial Sugar’s history.

Contaminated Worksites are a Leading Cause of Industrial Explosions

Contaminated worksites also rank among the leading causes of plant and refinery explosions.

Methane gas, for example, can enter groundwater through natural or industrial processes. If released, methane will form a highly combustible mixture when present in the air at concentrations between 5% and 15% volume. For this reason, it’s essential that industrial plants and refineries routinely test waters for the presence of methane gas.

Soil contaminants, including Trinitrobenzene (TNB), Dinitrobenzene, 2,4-dinitrotoluene (DNT), and 2,6-DNT, can also trigger fires and explosions if present in adequate concentrations. These and other dangerous sediments are frequently found in the dirt surrounding military facilities but may also be present near industrial sites, including plants and refineries.

OSHA Violations Contribute to the Vast Majority of Plant and Refinery Explosions

Our undefeated personal injury attorneys have successfully represented more than 1,000 plant and refinery workers in connection with the most catastrophic industrial explosions in recent history. And in every single case, an operator’s failure to comply with OSHA regulations and other accepted safety protocols was a significant contributor to those catastrophes.

In September 2005, for example, OSHA assessed BP a then-record $21 million fine in connection with the fatal Texas City Refinery explosion. The agency would later levy another $87 million fine against BP after determining that the company had breached the resulting settlement agreement.

Following the 2010 Kleen Energy explosion, OSHA inspectors uncovered nearly 400 safety violations, including many deemed to be deliberate disregards of safety protocol. Seventeen companies were eventually fined a total of $16.6 million in connection with the incident.

Most recently, the TPC Group received more than $500,000 in fines for OSHA violations uncovered in the wake of November 2019 Port Neches explosion.

Types of Injuries Sustained in Plant and Refinery Explosions

Plant and refinery work typically involves high temperatures, heavy machinery, volatile chemicals, and confined spaces. When something goes wrong in this environment, catastrophic and even fatal injuries are almost inevitable.

Burn Injuries

Fires, explosions, and exposure to hot equipment or steam can lead to serious burn injuries. These may range from first-degree surface burns to third-degree burns requiring skin grafts or long-term hospitalization. In some cases, chemical burns from exposure to caustic or corrosive substances may not be immediately visible but can cause internal damage and delayed symptoms.

Head Injuries

Falls, equipment malfunctions, and blast forces can cause head injuries ranging from concussions to life-altering traumatic brain injuries. Even a mild TBI can result in persistent headaches, memory issues, mood changes, and cognitive impairment. Severe cases can require years of rehabilitation and may permanently prevent a return to work.

Spinal Cord and Back Injuries

Crushing accidents, falls from height, and vehicle collisions within plant or refinery sites can lead to spinal cord injuries. Damage to the vertebrae or nerves may result in partial or complete paralysis. Even less severe back injuries—like herniated discs or muscle damage—can cause long-term pain and impair mobility.

Respiratory Injuries and Toxic Exposure

Inhalation of smoke, chemical fumes, or particulate matter can lead to immediate respiratory distress or long-term damage, including chronic obstructive pulmonary disease (COPD), asthma, or even cancer. Exposure to certain toxic substances, such as benzene or hydrogen sulfide, may not cause symptoms right away but can have serious long-term consequences.

Amputations and Crush Injuries

High-powered machinery and heavy loads increase the risk of crush injuries and amputations. These injuries may happen in an instant but often require months or years of recovery, including multiple surgeries and extensive physical therapy.

Orthopedic Injuries

Broken bones, torn ligaments, and joint injuries are common in both catastrophic accidents and day-to-day work involving physical strain. These types of injuries may not seem as severe initially, but they can still lead to chronic pain, limited range of motion, and long-term disability if not treated properly.

Psychological Trauma

Accidents don’t just leave physical scars. Survivors may also experience anxiety, depression, or post-traumatic stress disorder (PTSD), especially if they witnessed a fatal incident or suffered permanent injuries. Mental health care is an essential part of recovery, yet it’s often overlooked in the aftermath of a workplace disaster.

Texas Workers’ Compensation vs. Personal Injury Lawsuits

After a serious injury on the job, most plant and refinery employees assume they’ll be covered by workers’ compensation. However, unlike many other states, Texas doesn’t require private employers to carry workers’ compensation insurance.

If benefits aren’t available to you, you may have the right to file a personal injury lawsuit directly against the company. Even if your employer does carry workers’ compensation, that doesn’t prevent you from pursuing personal injury lawsuits against third parties that contributed to the accident. For example, if a defective piece of equipment exploded or a contractor failed to follow safety protocols, those entities may be held legally responsible.

So how does a personal injury differ from workers’ compensation?

- Workers’ compensation does not cover all of your damages like a personal injury lawsuit. Comp provides medical treatment for a specific period of time and a portion of lost wages.

- Personal injury claims allow injured workers and their families to seek damages not covered by workers’ comp, such as loss of future wages, future medical expenses, mental anguish, physical impairment, and pain and suffering. As a result, verdicts and settlements involve larger dollar amounts, especially in the case of catastrophic or fatal injuries.

In both cases, Texas sets strict time limits for filing either type of claim. Workers’ compensation claims must usually be reported within 30 days of the injury, while personal injury lawsuits generally must be filed within two years of the accident.

Why It’s Important to Hire an Experienced Refinery Accident Lawyer After an Industrial Accident or Explosion

After a plant or refinery explosion, the company and its insurance adjusters will do everything possible to prevent injured workers from receiving full compensation for lost wages, medical expenses, and pain and suffering.

You can’t place your future in their hands.

We understand the devastating physical and financial hardships plant and refinery explosions cause for workers and their families and are fully committed to ensuring that you receive the best medical treatment available and the financial resources needed to care for yourself and your family for the rest of your lives.

What You Can Expect from Our Undefeated Plant and Refinery Accident Lawyers

- We’ve won Billions for our clients and consistently recovered the #1 Largest Verdicts and Settlements in History

- We limit our caseload, so that we’re always available for and can focus on you and your family

- We assist you with everything from finding the best doctors and medical providers to setting up trusts and financial plans to protect your financial future when your case is resolved

- We’ll never accept anything less than the maximum compensation available

- Our lawyers begin preparing your case for trial from day one, so we’re ready to move forward in the event that the company refuses to offer a settlement that fully compensates you and your family for your injuries and losses

Our strategic approach and unparalleled commitment to our clients and their cases has distinguished Zehl & Associates as one of the Best Personal Injury Law Firms in the United States and resulted in the #1 Largest Verdicts and Settlements in History for our clients.

To see what other plant and refinery workers say about their experience with our firm, visit our Client Video Page or our firm’s YouTube Channel.

Undefeated Houston Plant & Refinery Injury Lawyers: Call 1-888-603-3636 or Click Here for a Free Consult

Having won Billions and successfully represented over 1,000 workers in connection with the worst industrial accidents and explosions in history, our Undefeated Plant and Refinery Explosion Lawyers have the resources, skills, and experience to stand up against the largest companies in the world and not only win, but set records.

If you or a loved one were seriously injured, catastrophically burned, or tragically killed in a plant or refinery accident, call 1-888-991-4702, use the “Chat Now” feature on our website, or click here to send us a confidential email through our “Contact Us” form.

We’ll explain your options, answer your questions, and ensure you have the information you need to decide what’s best for you and your family.

All consultations are free, and you won’t owe us a dime unless we win your case.

Plant and Refinery Video Resources

- Plant and Refinery Accident Information Page

- Our Success in Plant and Refinery Accidents

- Injured in a Refinery Accident: Who is Responsible?

- Profits Over Safety: the Most Common Cause of Plant and Refinery Accidents

- Refinery Explosion Victim Explains How Zehl & Associates Won Record-Setting Settlement for His Family

- Refinery Accident Victim Discusses How Zehl & Associates Secured his Future After Catastrophic Explosion

What Our Houston Clients Are Saying About Us

Read more of our Google reviews here.

Our personal injury law firm in Houston, TX, also provides:

- Aviation Accident Lawyers in Houston, TX

- Brain Injury Attorneys in Houston, TX

- Bus Accident Attorney in Houston, TX

- Car Accident Attorneys in Houston, TX

- Chemical Plant Attorneys in Houston, TX

- Defective Product Lawyers in Houston, TX

- Jones Act Lawyers in Houston, TX

- Maritime Accident Lawyers in Houston, TX

- Motorcycle Accident Attorney in Houston, TX

- Oilfield Accident Attorney in Houston, TX

- Railroad Crossing Accident Attorneys in Houston, TX

- Plant and Refinery Accident Lawyer in Houston, TX

- Swimming Pool Drowning Lawyer in Houston, TX

- Taxi Cab Accident Lawyers in Houston, TX

- Truck Accident Lawyer in Houston, TX

- Work Accident Attorneys in Houston, TX

- Wrongful Death Lawyer in Houston, TX

Plant & Refinery Accidents Infographic

FREE CASE REVIEW

Fill Out the Form Below for a Free Case Review with our Undefeated Personal Injury Lawyers

All communications are private and confidential. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.