Our world today revolves around the use of oil. We need it for transportation, heat, and many other uses. Much of this oil comes from oil rigs that are located offshore. About 15% of total U.S. crude oil production in a recent year was derived from offshore drilling in the Gulf of Mexico.

The oil and gas industry is significant in Texas, responsible for employing 480,176 workers in the state. Despite its importance, this industry is dangerous. Between 2015 and 2022, 2,101 severe work-related injuries, or 2.6% of all workplace injuries, were reported to OSHA in this industry.

The Beginning of Offshore Drilling

Oil is often found in seafloors. The first offshore drilling rig was built around 1891. Since then, these projects have expanded significantly. Today, offshore drilling rigs can drill 250 miles from the shore in waters up to two miles deep at depths of 28,000 feet below the seafloor.

The Process of Finding Crude Oil

Texas leases nine nautical miles from the shoreline to oil and gas companies to search for oil. The Outer Continental Shelf Lands Act gives the federal government the right to lease offshore land that extends beyond the state’s jurisdiction. Once the oil company purchases the leasing rights from the proper authority, it can begin searching for and identifying oil deposits.

Oil companies bounce sound waves on the seabed and record the response to determine where oil is likely to be deposited. Once a company identifies a place to drill an exploratory well, it must purchase a permit from the Bureau of Safety and Environmental Enforcement to drill a new well or modify one already in existence.

Different types of boats are used to drill the exploratory well, depending on the depth of water and sea conditions.

These rigs drill down into the ocean floor to try to identify if any oil and gas deposits are located there, using equipment such as:

- Riser – The riser is part of the drill that extends below the rig’s deck to the sea floor.

- Drill string – Drill strings are pipes that are lowered through the riser to drill into the seabed.

- Blowout preventer – This piece of equipment is used to close off pipes in case of a blowout.

- Metal casings – Workers use metal casings to stabilize the well and prevent it from collapsing.

- Cement walls – Cement walls line the metal casings.

- O-rings – These rings seal the spots where narrow metal casings join with larger casings.

If oil is found, workers install plugs to seal the well near the oil deposit. Workers drill mud, apply pressure to cover the plug, and set another at the top of the well.

The Process of Extracting and Transporting Oil

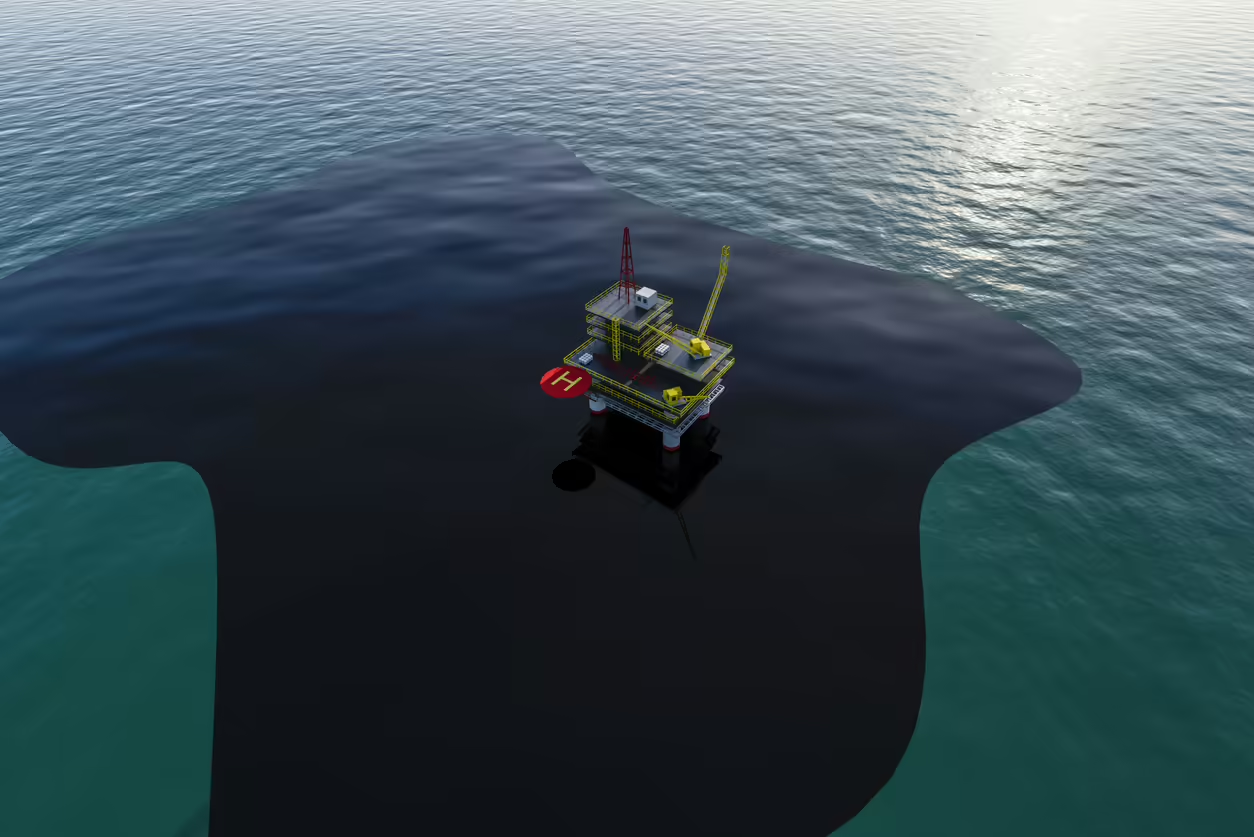

Once the location of oil is identified, oil companies use various production platforms to drill and extract the oil. The platform they use depends on the depths of the water where the oil is located, the distance from shore, and other factors.

The offshore production platform contains the equipment and crew members needed to keep offshore oil fields in production. The platform processes oil after extraction and transports it to the coast. These platforms sometimes have more than 100 workers operating on them at one time. One task these workers have is to build pipelines to transport oil from platforms to the shore.

Contact the Undefeated Houston Oil Rig Injury Lawyers from Zehl & Associates Injury & Accident Lawyers for Help Today

The process of identifying, extracting, and transporting oil can be dangerous, leading to many serious and fatal workplace injuries every year.

For more information, please contact our Undefeated Oil Rig Injury Attorneys in Texas at Zehl & Associates Injury & Accident Lawyers to schedule a free consultation today.

We proudly serve Harris County, Midland County, and throughout the state of Texas:

Zehl & Associates Injury & Accident Lawyers – Houston

2700 Post Oak Blvd #1000, Houston, TX 77056

(888) 603-3636

Open 24 hours

Zehl & Associates Injury & Accident Lawyers – Midland

306 W Wall St Suite 701, Midland, TX 79701

(432) 220-0000

Open 24 hours